Specialists in Static Control Products and PCB Cleaning and Repair Chemicals

Highly Effective, Premium Products You Can Trust

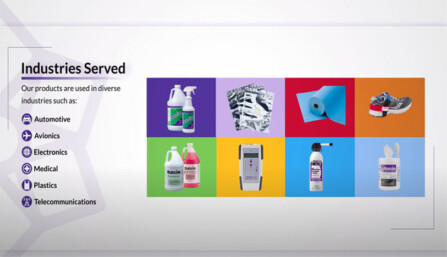

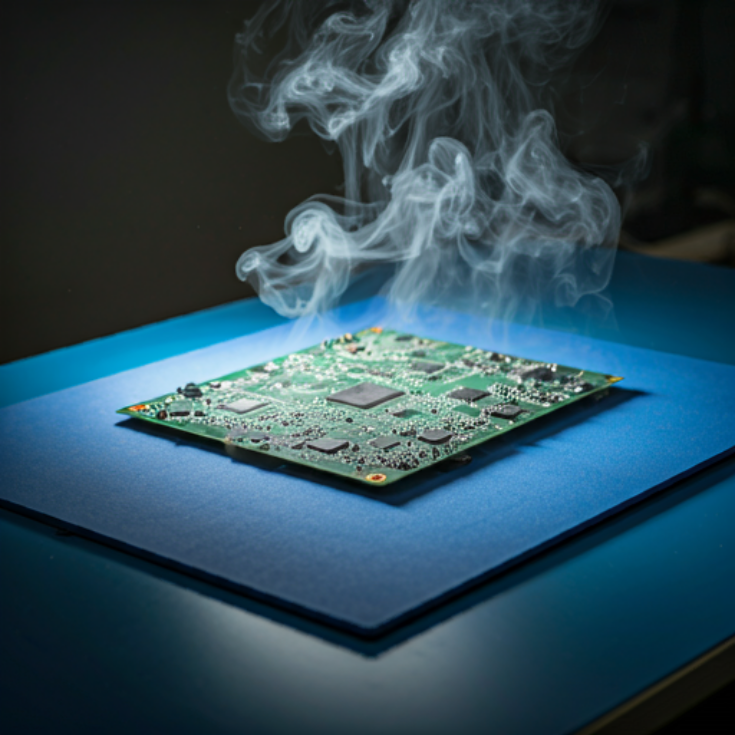

ACL Staticide® has been a trusted supplier to electronics manufacturers for over 50 years with products for the automotive, avionics, medical device, plastics, and telecommunications industries. From highly regarded static control products designed for ESD-protected areas, to contamination control products for critical environments, to enhanced precision preparation products for PCB rework, repair, and prototyping, ACL Staticide® is a worldwide leader.

Recognized for performance, quality, and innovation, ACL Staticide is dedicated to the highest level of customer satisfaction.

Friendly, knowledgeable sales staff for quick answers to your static control questions

Large inventory – most orders ship within 24 - 72 hours

Over 50 years of experience in static control and prevention

ISO 9001:2015 certification for our quality management system

Committed to regulatory bodies and industry standards

Watch Our Product Videos

ACL Staticide Company Video

For more than 50 years, ACL Staticide has been a trusted supplier of static control and specialized cleaning products. Our name is synonymous with quality, reliability, and cost-effective manufacturing solutions.

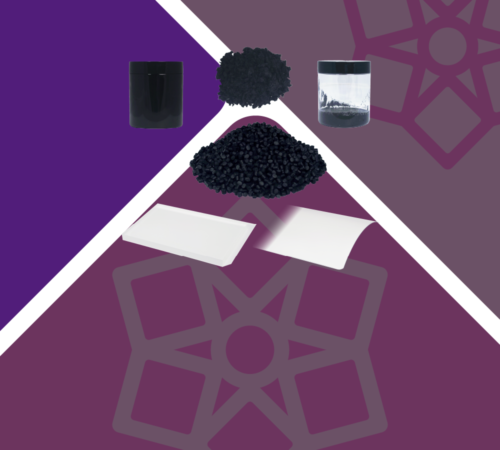

ESD Wastebasket & ESD Trash Bag Liners

ACL's Static Dissipative Wastebasket and Trash Bags are ideal for clean rooms, manufacturing, inspection, quality control and research industries where static control is crucial. Learn more about the benefits in our video.

ACL Staticide: Intro to ESD

ESD prevention plays a critical role in quality control programs in sensitive device manufacturing. Learn more about static control from this introductory video.

Read Our Latest Articles

Are Your Nitrile Gloves Putting Your EPA at Risk?

Posted on Thursday 05th December, 2024

Disposable nitrile gloves are a staple in various industries, including healthcare and manufacturing. They are essential in laboratories and electrostatic-protected areas...

Read more

Ensuring ESD Floor Protection During Winter

Posted on Wednesday 20th November, 2024

As the winter months approach, it's important to consider the impact cold weather can have on your static control areas, especially regarding floor maintenance. While Low...

Read more

Protecting Electronics with Low-Outgassing ESD Mats

Posted on Monday 18th November, 2024

A product's outgassing performance is often just as crucial as its mechanical and electrical specifications, especially when used in sensitive device and printed circuit...

Read more